|

|

||||||||

|

|

|

|||||||||

|

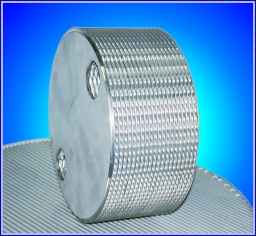

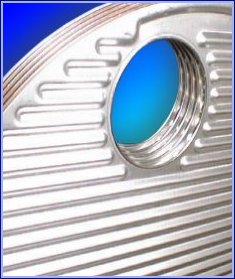

The fully welded Caloperm heat exchanger combines

the best features of plate heat exchangers and shell & tube heat exchangers. The heat exchange area consists of a pack of profiled stainless steel plates alternately welded together at the outer and inner diameter. Fitted with end tubes the plate pack is brought in position inside the shell, all the support is assembled and finally all components are welded together to the complete gasket free Caloperm heat exchanger. |

|||||||||

|

Like traditional plate heat exchangers

the profiled

|

||||||||

And as in the shell & tube technology the units are

|

|||||||||

|

Each Caloperm plate heat exchanger is designed and manufactured

for your specific operating conditions. The heat exchanger plates are welded together with a robot welding system. Non destructive test procedures during the manufacturing ensure unchanged high quality of the plate packs. The production process is controlled by a quality system according to ISO 9001 and PED 2014/68/EU. |

|||||||||

|

Working principle of the Caloperm heat exchangerThe plates are welded together alternately on the outer diameter and in the connection holes. Thereby a plate pack is formed with alternating channels for hot and cold media. The welded connection holes form the inner channel. At its end, this channel is fitted to the connecting pipe leading out of the shell. The shell channel goes straight through the plate pack. After assembling all components, the apparatus is totally welded together. This results in a gas tight unit, being able to handle high temperatures and high pressures as well as aggressive media on both sides. The Caloperm heat exchanger can be delivered on the plate as well as on the shell side as one pass unit or more pass unit. |

||||||||

|

Products |

|||||||||

|

Calopyx heat exchanger

|

||||||||

|

Calodux heat exchanger

|

||||||||

|

Duopyx heat exchanger

|

||||||||